Checking out the Duty of Aluminum Casting in the Development of Industrial Manufacturing

Aluminum casting has actually played a crucial duty fit modern-day commercial production. Its durable and light-weight nature has changed the production of parts for numerous sectors, consisting of vehicle and aerospace. With improvements in casting strategies, the industry has seen enhancements in accuracy and efficiency. As sustainability ends up being significantly crucial, the recyclability of light weight aluminum includes one more measurement to its value. What effects does this have for the future of making practices?

The Origins of Light Weight Aluminum Casting

Light weight aluminum casting has a rich background that goes back to the late 19th century when the adaptability of light weight aluminum was very first recognized. Originally, this lightweight metal was deemed challenging to collaborate with because of its high melting point and sensitivity to oxidation. Cutting-edge minds began to discover its possibility, leading to the development of different casting techniques. The introduction of light weight aluminum into commercial applications noted a substantial transition in manufacturing, permitting the production of detailed elements that were previously unattainable with various other metals. By the very early 20th century, light weight aluminum casting had acquired traction in numerous markets, from vehicle to aerospace, owing to its stamina and light-weight buildings. The establishment of foundries and the introduction of aluminum alloys even more thrust its popularity, setting the stage for future improvements. The origins of aluminum spreading laid the groundwork for its important duty in modern industrial manufacturing.

Trick Advancements in Aluminum Casting Techniques

Current innovations in aluminum spreading techniques have substantially changed commercial manufacturing. Innovations in die casting procedures have improved accuracy and efficiency, while the development of sand casting has actually enhanced versatility and cost-effectiveness. These growths are reshaping the landscape of light weight aluminum manufacturing and expanding its applications throughout various sectors.

Pass Away Spreading Innovations

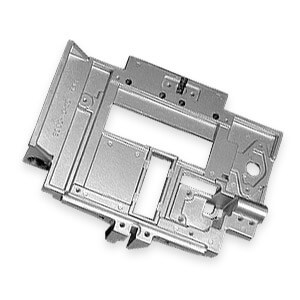

As industries venture for enhanced efficiency and item high quality, pass away spreading has actually become a centerpiece for advancement in aluminum casting strategies. Current developments have concentrated on boosting mold and mildew style, temperature control, and product buildings, markedly lowering cycle times and raising accuracy. The introduction of computer-aided design (CAD) and simulation software has actually allowed manufacturers to maximize pass away geometries and forecast potential defects prior to production. In addition, the integration of automated systems has streamlined operations, enhancing consistency and lowering human error. Advancements such as vacuum die casting and semi-solid metal spreading have additionally enhanced the mechanical homes of light weight aluminum components, bring about lighter, stronger items. These improvements placement pass away spreading as a crucial aspect in the affordable landscape of contemporary manufacturing.

Sand Spreading Evolution

Innovations in light weight aluminum spreading strategies have not been restricted to pass away spreading; sand casting has actually additionally undertaken substantial evolution. Generally reliant on hands-on processes, modern sand casting has welcomed automation and digital innovations, improving efficiency and precision. Advancements such as computer-aided design (CAD) allow for even more elaborate mold and mildew designs, while 3D printing of sand molds has reinvented production times and reduced product waste. Additionally, the intro of sophisticated sand blends enhances the surface finish and mechanical properties of actors parts. These advancements not just lower manufacturing prices however also expand the range of applications for sand-cast light weight aluminum products. As industries require better and faster turnaround, the advancement of sand spreading continues to be essential in meeting these modern manufacturing challenges.

The Influence of Light Weight Aluminum Casting on the Automotive Market

Aluminum spreading has reinvented the automotive market by enabling the manufacturing of lightweight parts that boost lorry performance. These innovations add substantially to enhanced gas effectiveness, aligning with environmental criteria and customer demands (aluminum casting). Furthermore, the convenience of light weight aluminum casting promotes design adaptability, enabling cutting-edge methods in automobile manufacturing

Light-weight Part Advantages

The automotive industry has actually progressively embraced light-weight components to enhance fuel efficiency and performance. Light weight aluminum spreading has actually become an essential modern technology in this change, allowing suppliers to create parts that are not only lighter however likewise structurally robust. These light-weight components add to improved vehicle dynamics, making it possible for much better handling and acceleration. In addition, light weight aluminum's deterioration resistance extends the lifespan of auto components, reducing upkeep costs gradually. The flexibility of light weight aluminum spreading permits elaborate styles that were previously unattainable, promoting innovation in vehicle visual appeals and performance. As automotive suppliers remain to prioritize sustainability, using light-weight aluminum cast elements straightens with efforts to lower general automobile weight, marking a substantial innovation in auto engineering.

Boosted Fuel Effectiveness

As the vehicle industry looks for cutting-edge methods to improve gas performance, light weight aluminum spreading has become a pivotal remedy. The light-weight properties of light weight aluminum greatly reduce vehicle weight, leading to enhanced gas economic situation. By substituting heavier materials with aluminum cast components, manufacturers can enhance engine efficiency and lessen energy usage. This change not only assists in lowering greenhouse gas exhausts yet additionally aligns with global sustainability objectives. Additionally, aluminum's superb thermal conductivity enables for much better warmth dissipation in engines, even more improving performance and efficiency. As an outcome, cars making use of light weight aluminum cast parts can achieve higher miles per gallon, appealing to eco-conscious customers and conference rigorous regulative criteria. This innovation highlights aluminum's essential function in the future of automotive manufacturing.

Design Adaptability and Innovation

While typical products frequently impose limitations on style, aluminum spreading provides unequaled versatility that promotes development in the auto sector. This versatility permits manufacturers to create intricate geometries and intricate functions that were previously unachievable. Light-weight light weight aluminum elements can be customized to satisfy details efficiency requirements, enhancing both automobile efficiency and looks. Furthermore, the spreading process supports fast prototyping, allowing quicker iterations and lowering time-to-market for new layouts. As car manufacturers increasingly focus on sustainability, light weight aluminum's recyclability enhances style initiatives, advertising environment-friendly methods. On the whole, light weight aluminum spreading equips engineers and developers to press the click to find out more boundaries of creative thinking, bring about the growth of innovative automobiles that fulfill modern-day customer demands for efficiency, security, and ecological responsibility.

Developments in Aerospace Via Aluminum Spreading

Aluminum spreading has changed the aerospace sector by making it possible for the manufacturing of lightweight yet highly durable elements. This technology allows for the development of intricate shapes that typical manufacturing methods can not achieve, causing improved performance and effectiveness in airplane style. Trick applications include engine components, architectural components, and detailed assemblies that benefit from aluminum's excellent strength-to-weight proportion.

Innovations in casting methods, such as high-pressure die casting and investment casting, have actually boosted dimensional precision and surface coating, decreasing the requirement for considerable machining - Aluminum Foundry. These developments simplify manufacturing procedures, reduce lead times, and reduced manufacturing prices, making aluminum elements progressively appealing to aerospace designers

Additionally, the capacity to integrate multiple features right into a solitary cast component decreases assembly time and possible factors of failing. Because of this, aluminum spreading remains to play a vital function beforehand aerospace innovation, adding to the advancement of more secure, extra effective, and eco pleasant aircraft.

Sustainability and Environmental Benefits of Aluminum Casting

The aerospace market's shift towards aluminum casting not just boosts efficiency however additionally contributes favorably to sustainability initiatives within commercial production. Light weight aluminum casting deals considerable environmental benefits, largely due to aluminum's integral recyclability. Approximately 75% of light weight aluminum produced is still in use today, showcasing its possibility for circular economy practices. The power required to reuse aluminum is markedly lower-- up to 95% less-- compared to generating brand-new light weight aluminum from ore.

Furthermore, aluminum spreading procedures typically generate less waste, as sophisticated methods enable the effective usage of products. This reduces the ecological influence related to manufacturing. The lightweight nature of light weight aluminum likewise leads to a lot more fuel-efficient airplane, minimizing greenhouse gas discharges during operation. In general, the assimilation of light weight aluminum casting in commercial manufacturing not just sustains cutting-edge layout and performance however additionally straightens with global sustainability objectives, making it a critical choice for environmentally mindful markets.

The Future of Light Weight Aluminum Casting in Production

Advancements in alloy development are anticipated to improve the residential or commercial properties of actors aluminum, making it lighter and more sturdy (aluminum casting). These improvements will certainly not just fulfill the expanding needs of industries like automotive and aerospace but additionally add to ecological goals by minimizing energy usage. Eventually, the future of light weight aluminum casting in production shows up positioned for a standard shift, driven by innovation's ability to innovate and optimize manufacturing procedures

Often Asked Questions

How Does Light Weight Aluminum Casting Compare to Various Other Metal Casting Procedures?

Aluminum casting deals benefits such as lower weight, enhanced corrosion resistance, and far better thermal conductivity compared to various other steel casting procedures. It may be much less suitable for high-temperature applications than products like steel or iron.

What Are the Key Safety Concerns in Light Weight Aluminum Spreading?

The main safety and security problems in aluminum spreading include direct exposure to thaw steel, potential burns, inhalation of hazardous fumes, and threats linked with devices operation. Proper safety protocols and personal protective equipment are vital to minimize these threats.

Can Light Weight Aluminum Casting Be Used for Artistic Purposes?

Aluminum casting can indeed be used for creative purposes. Artists frequently value its convenience, light-weight nature, and capacity to record complex information, permitting the creation of both ornamental and functional pieces that showcase imagination and craftsmanship.

What Are the Expenses Connected With Light Weight Aluminum Casting?

Just How Has Aluminum Casting Influenced Global Production Trends?

Light weight aluminum spreading has considerably affected global production patterns by providing light-weight, durable elements, lowering production prices, and boosting layout versatility. Its fostering throughout numerous markets has structured processes and promoted development, shaping contemporary manufacturing techniques worldwide.

Aluminum spreading has an abundant history that dates back to the late 19th century when the convenience of light weight aluminum was very first recognized. As industries venture for boosted effectiveness and item top quality, pass away spreading has arised as a focal factor for technology in light weight aluminum casting methods. Advancements such as vacuum cleaner important site die spreading and semi-solid metal spreading have actually even more enhanced the mechanical residential properties of aluminum parts, leading to lighter, stronger items. Improvements in light weight aluminum casting strategies have actually not been limited to pass away casting; sand casting has additionally undertaken considerable development. Light weight aluminum casting offers substantial ecological advantages, largely due to light weight aluminum's intrinsic recyclability.